Rubber Flooring

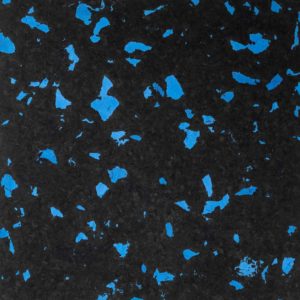

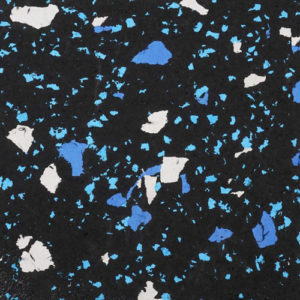

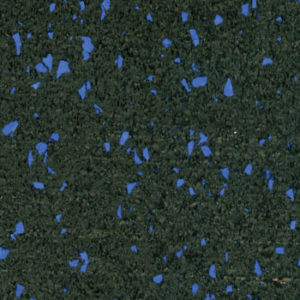

Rubber flooring is durable, water-resistant, anti-fatigue, and shock absorbent, making it a prime choice for anyone seeking flooring. Allied Products offers an extensive selection of rubber flooring in multiple thicknesses and color options

SEE PRODUCTSFREE QUOTE Commercial Rubber Flooring

Our dense, resilient rubber flooring options provide both maximum comfort and shock absorption – perfect for most commercial applications. Our rubber flooring options can be customized to fit your application, and come in a variety of thicknesses.

Browse our product inventory below, or give us a call for a custom quote.

Common Rubber Flooring Applications:

- Fitness Flooring

- Health Clubs

- Locker Rooms

- Indoor Play Areas

- Outdoor Recreation

- Running Tracks

- Functional Training Rooms

- Weight Rooms

Commercial Rubber Flooring Products

Types of Rubber Flooring

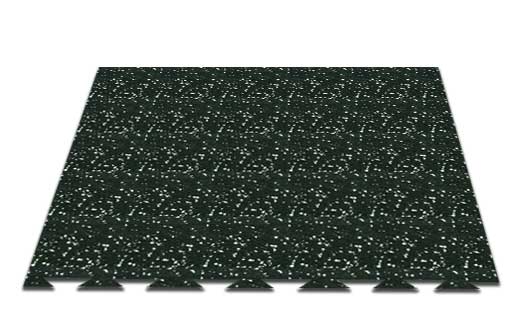

Interlocking Floor Tiles and Athletic Flooring. We have rolled rubber as well as interlocking rubber tiles that simply snap together like a puzzle. Both offer extreme durability and come in different color options.

Our rubber flooring rolls are made of reused materials so this type of flooring exceeds the requirements set forth in Executive Order 13101 Greening Government. Our rubber flooring can also be a contributing factor towards LEED Green Building Council certification.

Interlocking Floor Tiles and Athletic Flooring. We have rolled rubber as well as interlocking rubber tiles that simply snap together like a puzzle. Both offer extreme durability and come in different color options.

Our rubber flooring rolls are made of reused materials so this type of flooring exceeds the requirements set forth in Executive Order 13101 Greening Government. Our rubber flooring can also be a contributing factor towards LEED Green Building Council certification.

Installation of Rolled Rubber Flooring

- When laying down the flooring, always make sure the roll curl is facing down to prevent the flooring from curling up.

- Place the roll end against the wall and unroll the flooring over the sub surface. If the length of the flooring exceeds the area space use a sharp straight edge knife to trim the excess flooring. It is recommended to leave an extra inch that will be be removed during the final cutting. It is highly recommended that all of the flooring be cut with an extra inch to allow for any changes or adjustments as needed.

- Once all of the flooring has been measured and cut it is very important to allow the flooring to acclimate to both the room and ground temperature.

- Once this has been completed the final trimming can occur to align for a perfect fit.

- Apply adhesive according to manufacturer’s recommendations.

- Within an hour of the adhesive being applied it is strongly recommended that the flooring be rolled with a 50-100 lb carpet roller to assure bonding of the adhesive to the rolled rubber flooring. Rolling should be done twice, once widthwise and the other lengthwise. This results in maximum bond of between the flooring and adhesive.